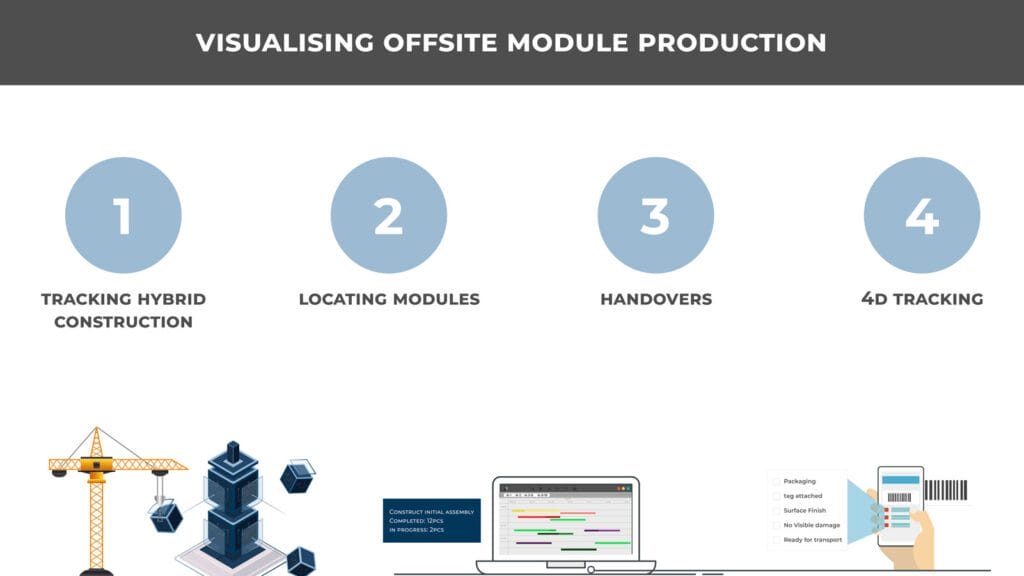

1

TRACKING HYBRID CONSTRUCTION

Most modern construction sites utilise some kind of hybrid construction methods where subassemblies or modules are manufactured or assembled separately and then delivered for final assembly at the correct time at the correct location. At Visilean Ltd we’ve given some thought to how this hybrid process of traditional onsite construction together with module delivery could be visualised to make handovers smooth and so that correct information is always available at the right time. Established project management tools and simple spreadsheets do not cope well with visualisation and the real-time nature of the construction site.

2

LOCATING MODULES

Manufacturing, transport and construction activities should be visualised in different ways. For example, the prerequisites for starting a construction task will be totally different from starting a transport activity for a module. Also, being able to see GPS location of the modules makes it possible to visualise even the major material deliveries on a map, whereas on the construction site, the map location isn’t changing, but instead the sectioning of the building is of more importance.

3

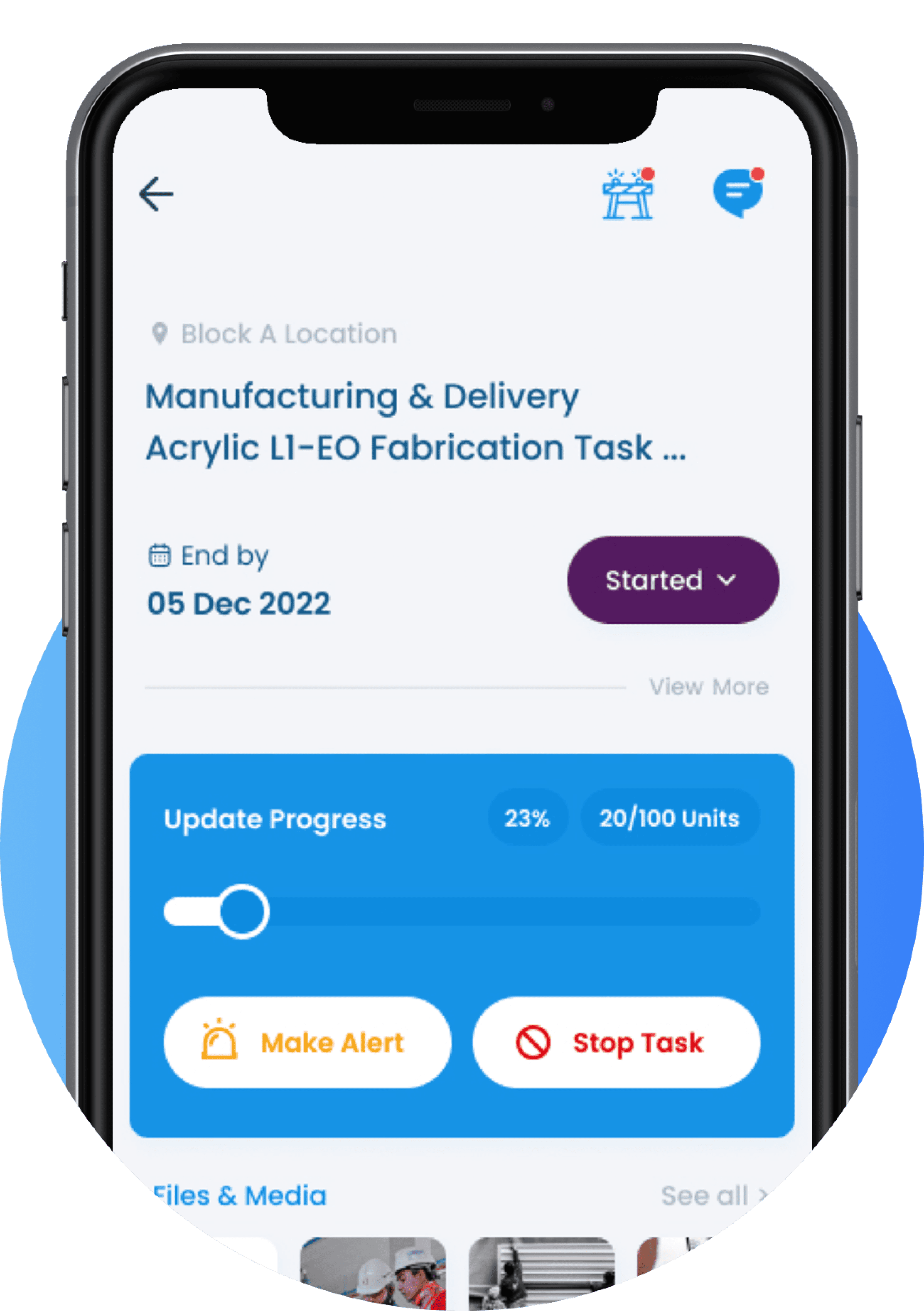

HANDOVERS

Handovers, like from manufacturing to transport, should be done with mobile devices wherever possible using bar codes or RFID tags. With customised checklists it’s possible

to ensure that the prerequisites are reviewed and that they then are hooked up in real time to the status indicators for the tasks or for the assemblies themselves.

4

4D TRACKING

Normally, 4D views are used as simulation tools to, among other things, ensure that the master construction plan works properly and that the work progresses in the right order, with the right material and the right resourcing. We’ve implemented 4D tracking to show the model colour as it’s actually being built right now, showing completed work, work in progress and uncommitted work with separate colour in the 3D model. But with the added dimension of subassemblies and modules, it’s now desirable to visualise another

dimension in the 3D model – the actual “matureness” of a module – planned, in production, being shipped, in construction. In this way any quality alerts found during handover could be visualised in the 3D model, too, so it’s possible to take corrective actions immediately.